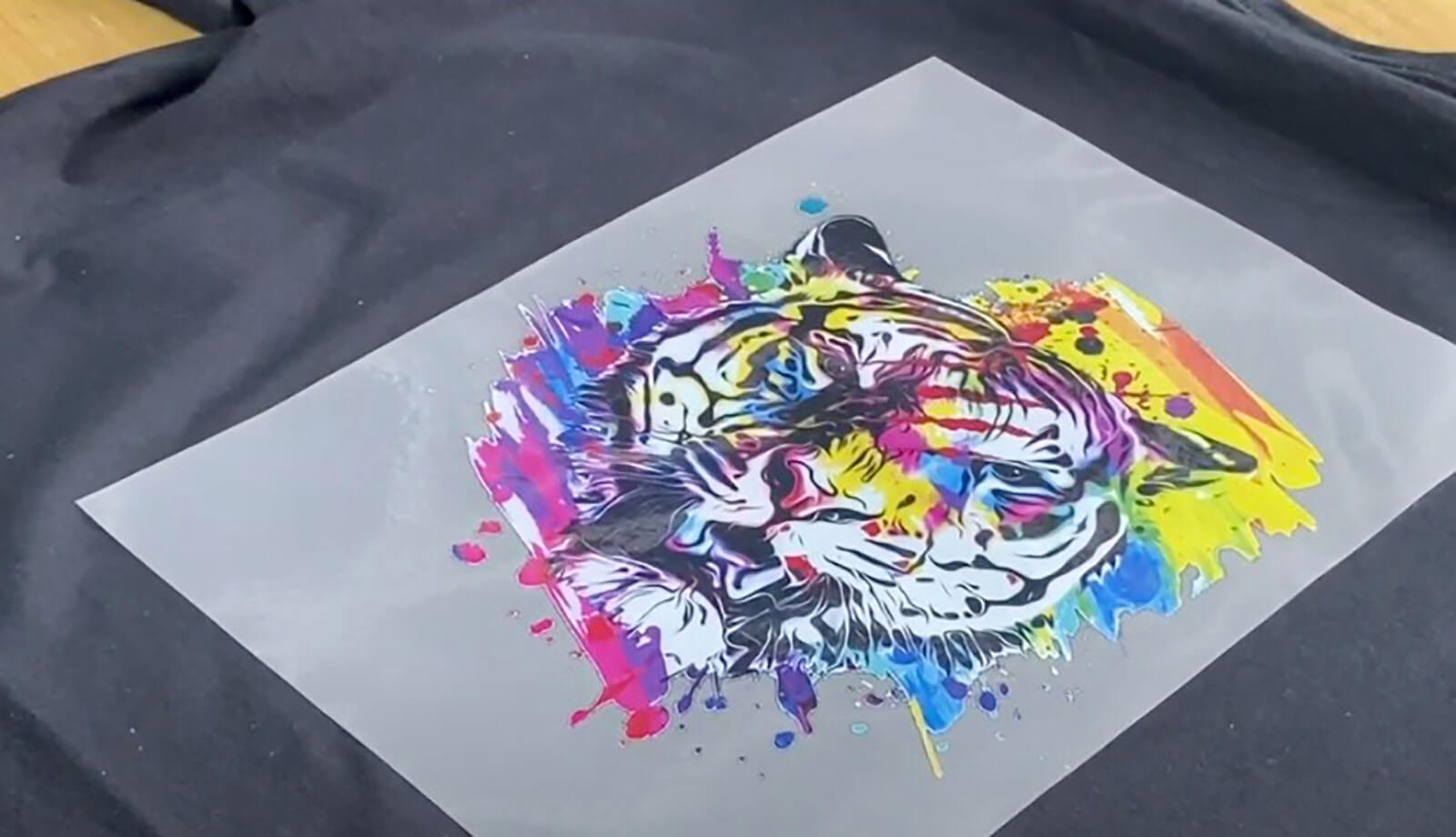

Custom Direct-to-Film (DTF) transfers are an innovative method for transferring designs onto various surfaces, including fabric, metal, and plastics. The success of DTF printing relies significantly on selecting the right materials. Here’s a rundown of the best materials for achieving high-quality and durable custom DTF Transfers.

1. High-Quality Transfer Films

The film used in custom DTF Transfers is crucial for achieving vibrant and long-lasting prints. High-quality transfer films, typically made from polyester or PET (Polyethylene Terephthalate), are preferred. These films offer excellent ink adhesion and ensure that the design stays intact during the transfer process. Films with a glossy finish are often chosen for their ability to produce vibrant colors and sharp details.

2. Specialty DTF Inks

DTF inks are specially formulated to work with the transfer films and the heat transfer process. Pigment-based inks are commonly used because they provide bright, durable colors and are less prone to fading. High-quality inks also ensure better color accuracy and consistency, making them essential for professional-grade transfers.

3. Adhesive Powders

Adhesive powders are used to bond the ink to the transfer film. These powders are usually applied to the wet ink before the curing process. Choosing the right adhesive powder is important for ensuring that the design adheres properly to the target surface. Powder with fine granules ensures even coverage and prevents clumping, which can affect the quality of the final print.

4. Transfer Paper

While not always a necessity, transfer paper can be used in conjunction with DTF films to enhance the transfer process. It helps in handling the film and maintaining the integrity of the design during application. Opt for high-quality transfer paper that is compatible with DTF films to avoid issues like smudging or uneven transfers.

5. Target Surface Materials

The surface material onto which the DTF transfer is applied also affects the outcome. Fabrics like cotton, polyester, and blends are popular choices for apparel. For hard surfaces, such as metal or plastics, ensure that the surface is clean and properly prepared to enhance adhesion. Pre-treatment may be required for certain materials to ensure a smooth transfer.

Choosing the best materials for custom DTF transfers is crucial for achieving high-quality, durable, and vibrant results. By selecting high-quality transfer films, specialty DTF inks, reliable adhesive powders, and compatible transfer papers, you can ensure that your custom transfers stand out and last. Additionally, preparing the target surface properly will further enhance the final product. With the right materials, your custom DTF projects can reach their full potential, showcasing beautiful, long-lasting designs.